Expertise

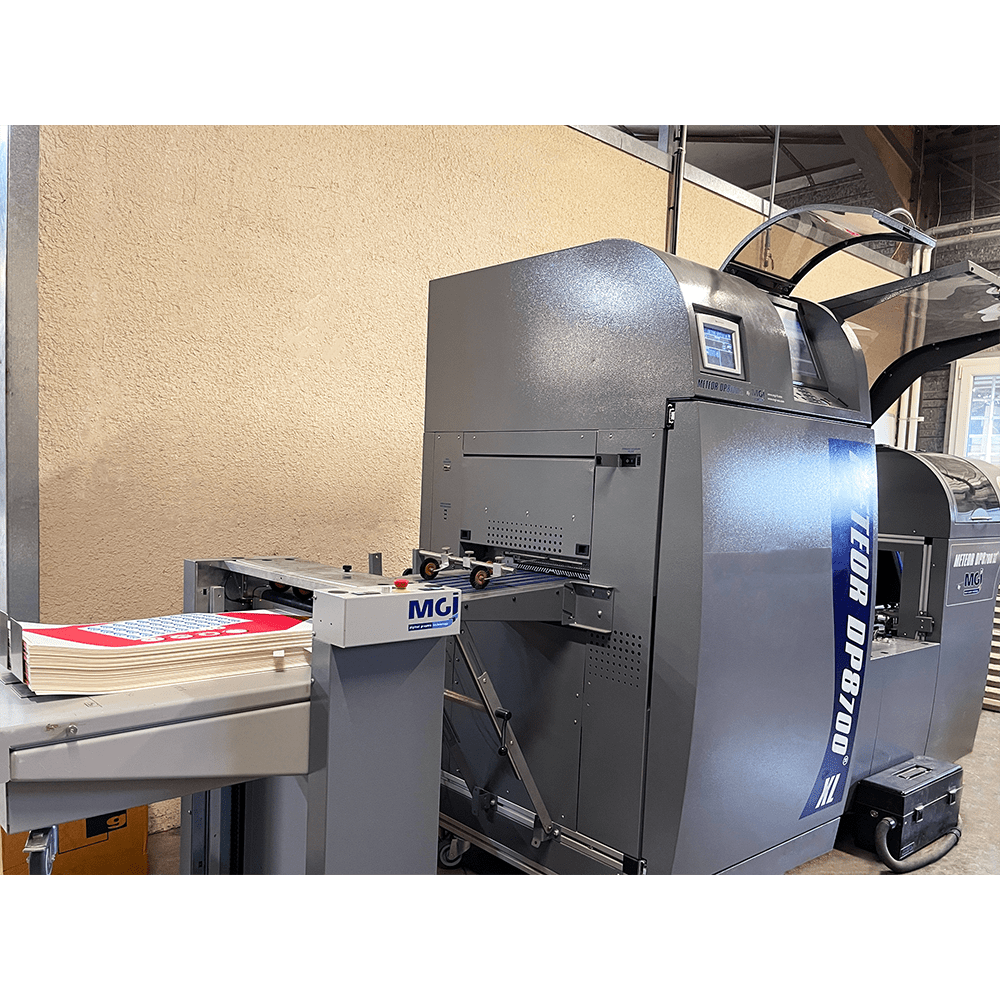

Industrial printing

Discover our expertise in industrial printing

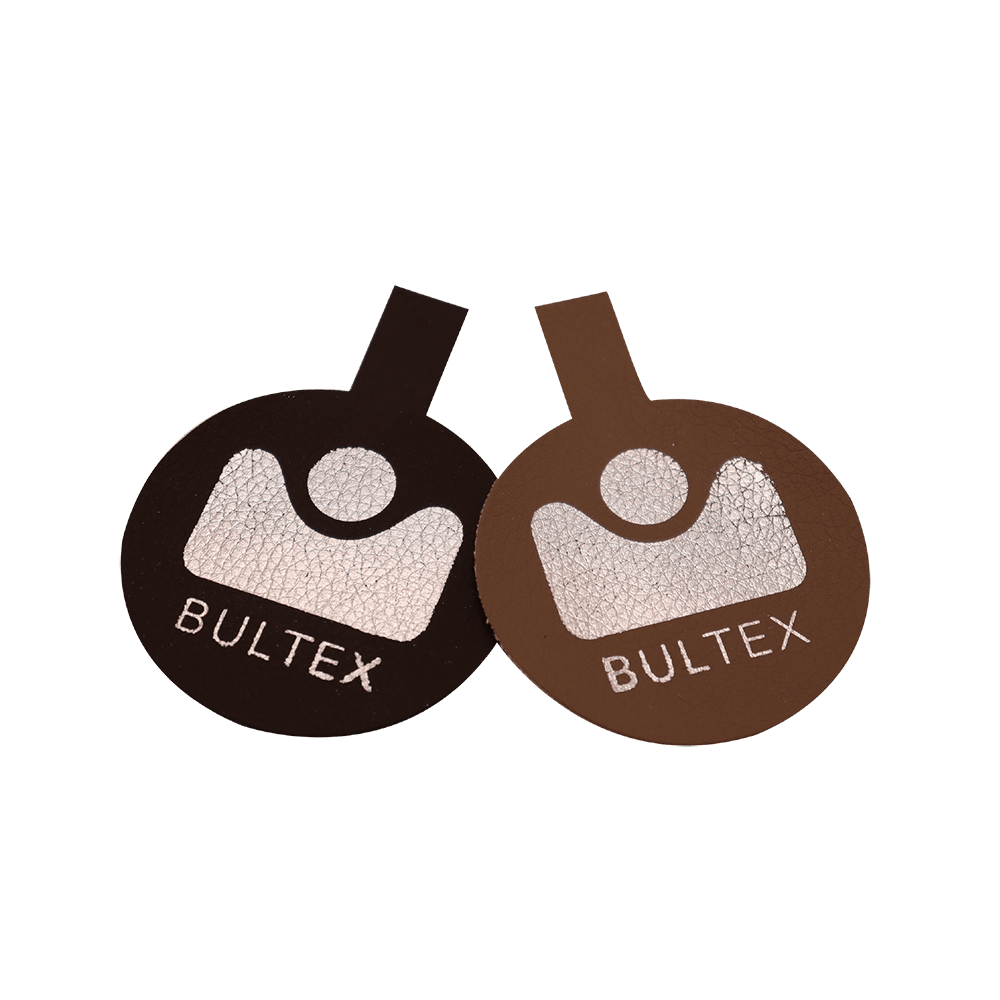

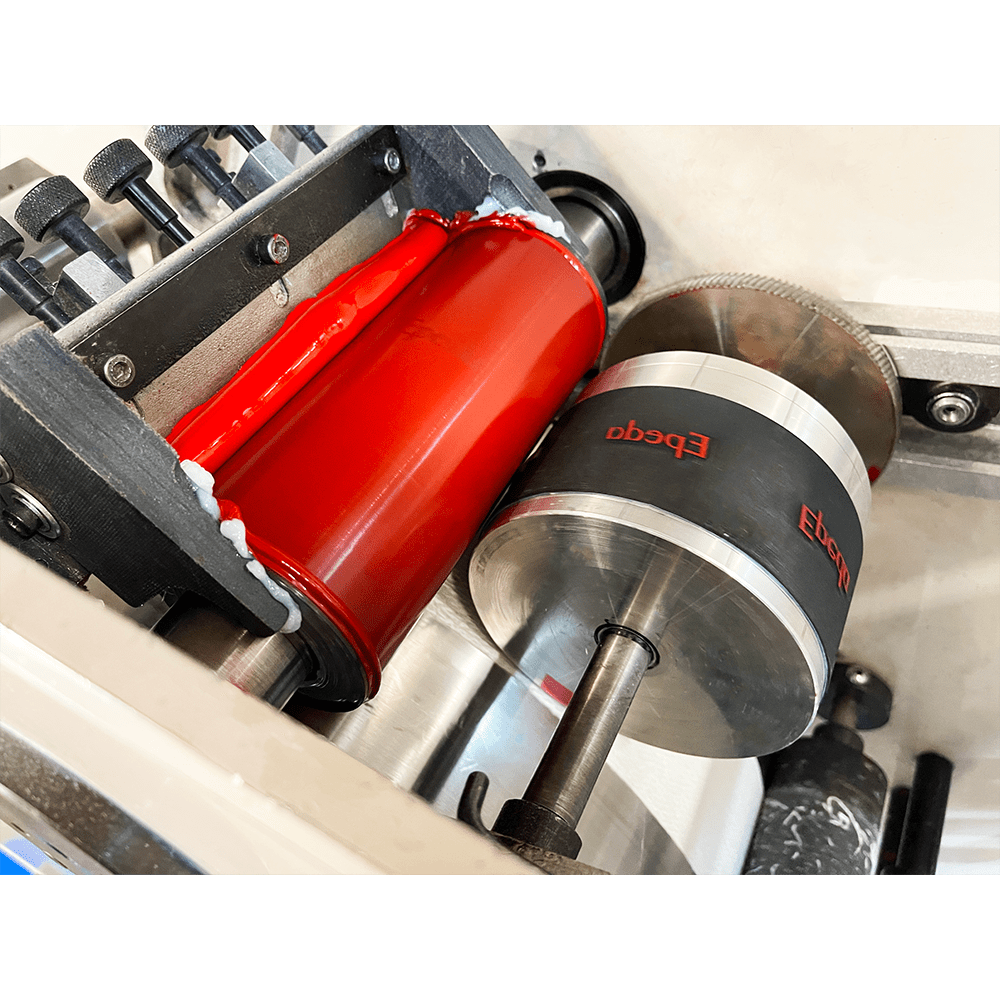

For over 25 years, industrial textile printing has been part of our know-how. Offset, digital, thermal, silk-screen and flexographic printing, LOUISON INDUSTRIES has specialized and developed the mastery of printing technologies to offer you a qualitative, innovative and personalized finish in order to stand out on all paper and textile supports.

Industrial printing is the integration of printing technologies into a manufacturing process. Used for functional or simply decorative purposes, it involves the printing of ink or other substance onto a textile or paper substrate.

OUR APPROACH

Consulting, research and manufacturing

Our innovative approach allows us to accompany you as a true partner, from the project idea to the industrialization of the finished product.

Consulting

Our extensive experience in the world of textiles and plastics processes enables us to advise and guide you in your choice of products. If you encounter technical problems with one of your textile or plastic products, we are here to find solutions. Tell us about your projects so that we can help you solve your problems. We are no longer just your supplier, we become your partner!

R & D

Basic and experimental research is in the company's DNA. We are always on the lookout for new technologies from our suppliers and partners, so that we can offer you the most innovative solutions on the market. Our 2 laboratories allow us to carry out all kinds of research, development and tests quickly in order to develop and perfect new manufacturing processes and new materials.

Manufacturing

We are able to design products from existing models or we can create a new product based on your specifications or a jointly developed specification. We study the constraints linked to the realization of your product, and we propose the most economical solution that meets your needs. If we can integrate a large part of eco-responsibility from the design stage, we will do so with passion.

Know-how of the company

Offset

Digital

Thermal

Screen printing

Flexography

A project?

Contact us

With LOUISON INDUSTRIES, benefit from more than 140 years of know-how and experience in the field of textiles and plastics processes.