Discover our expertise in industrial printing

For over 25 years, industrial textile printing has been part of our know-how. Offset, digital, thermal, silk-screen and flexographic printing, LOUISON INDUSTRIES has specialized and developed the mastery of printing technologies to offer you a qualitative, innovative and personalized finish in order to stand out on all paper and textile supports.

Industrial printing is the integration of printing technologies into a manufacturing process. Used for functional or simply decorative purposes, it involves the printing of ink or other substance onto a textile or paper substrate.

Know-how of the company

We offer numerous industrial printing processes for paper and textiles.

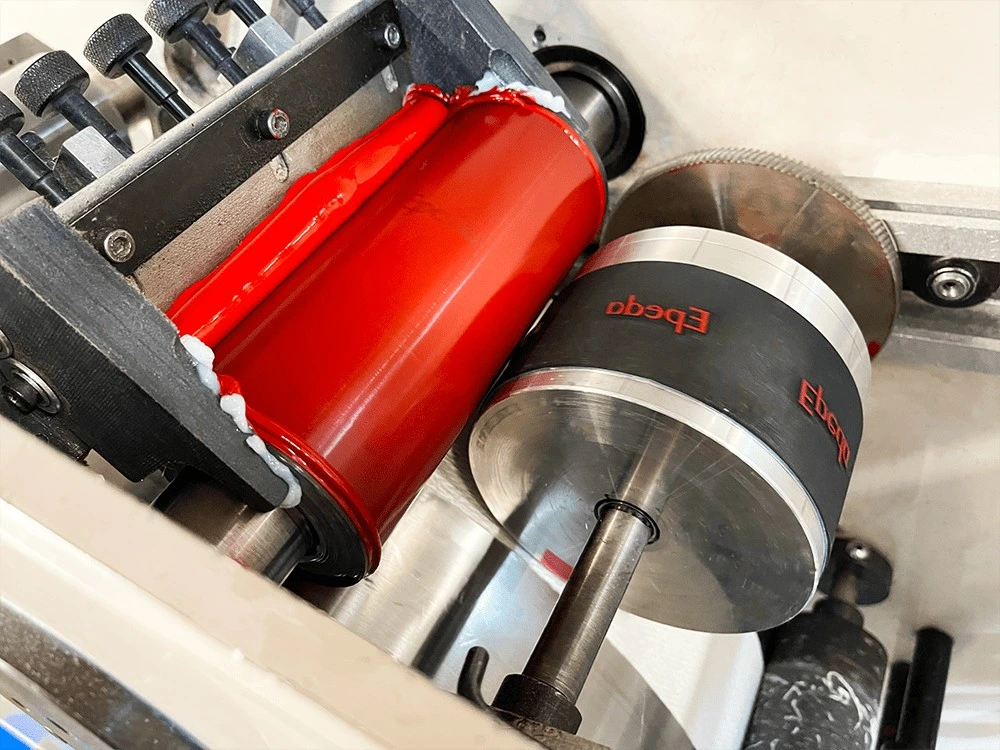

Offset printing

This very old printing technique relies on the use of plates (one per colour) that transfer the image to an intermediate cylinder, the blanket. The image is then printed onto the final medium (fabric or paper).Offset printing is the most commonly used technique for large print runs (over 500 copies).

Screen printing

This printing technique is based on the use of a stencil. It can be used on a wide range of materials and is particularly well suited to textile printing. As each colour is printed separately, it is ideal for simple designs and brand logos.

Digital printing

This technique allows printing directly onto the medium from computer data. It is well suited to rapid printing in small runs. It also makes it easy to carry out layout and colour tests and to print on a large scale.

Flexography

This technique works on the same principle as an ink pad. The ink is applied to a flexible raised surface, which then transfers the design onto the final medium (usually cardboard or paper). It is a fast, high-productivity printing method, widely used for personalising packaging and printing food labels

Thermal printing

This process does not use ink: it is the paper that changes colour under the effect of heat. This method is fast and economical, but the print is less durable over time due to its sensitivity to UV light. This technique is preferred for temporary prints, such as receipts and shipping labels.

A project ?

Contact us

With LOUISON INDUSTRIES, benefit from more than 140 years of know-how and experience in the field of textiles and plastics processes.