Fabric and paper sizing applications

The sizing of fabrics and textile products offers a diverse range of applications, making Louison Industries an essential partner for many industries. In the FMCG sector, our sizing enables textiles to be reinforced for increased durability, offering superior quality to finished products.

In addition, we offer sizing solutions for various textiles used in the manufacture of garments, bags and accessories. In stationery, gluing is used to create cards, albums, books, etc.

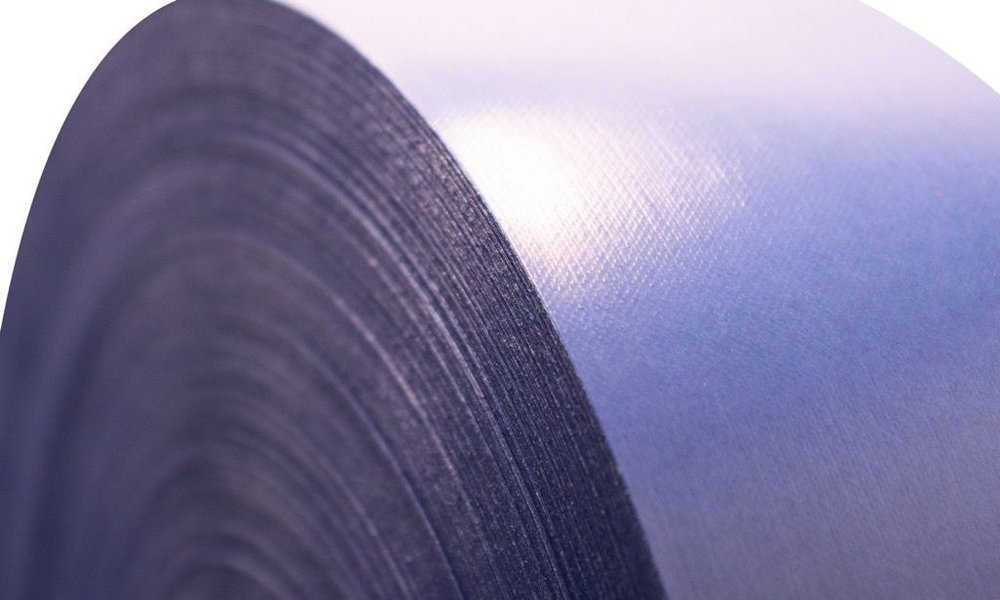

Materials suitable for sizing

Louison Industries can perform sizing on a variety of textile materials such as cotton, polyester, nylon, silk and many others. Our sizing processes are also suitable for different types of paper used in industry. We carry out extensive tests to determine the best sizing process for the specific material and customer requirements, guaranteeing optimum adhesion and a high-quality finish.

Sizing process

Our fabric and textile sizing process is designed to meet the specific needs of each customer. Direct gluing provides a strong, permanent bond, ideal for applications requiring a solid adhesion. Thermobonding, on the other hand, uses a heat-activated adhesive base, enabling thickness to be adjusted according to the material, offering greater flexibility. Finally, pure adhesive bonding is the perfect solution for solidifying and stiffening textile structures, guaranteeing optimum resistance in a variety of environments.

Direct gluing: environmental benefits

We are committed to offering top-of-the-range finishes while respecting the environment. Our eco-responsible suppliers enable us to use environmentally-friendly adhesives, reducing our ecological footprint. In addition, our gluing processes are designed to minimize the waste of raw materials and optimize the use of resources, contributing to a sustainable approach in our industry.

Thermobonding : an innovative and sustainable solution

Thermobonding is one of Louison Industries’ most innovative and durable solutions for bonding fabrics and textile products. The process consists of applying a heat-activatable adhesive base, offering a strong, flexible bond according to the thickness of the chosen material. The thinner the substrate to be coated, the more heat-activated it becomes, making it a suitable option for a variety of applications, from delicate textiles to thicker fabrics.

Pure adhesive bonding: strength and resistance

Pure glue bonding is an essential method for solidifying and stiffening textile structures. We use this technique to strengthen fabrics and give them significant resistance to a variety of environments. This solution provides a strong, durable bond, ensuring that finished products meet the highest quality standards, making it a reliable choice for demanding applications.

FAQ | Sizing fabrics and stationary

Fabric gluing is commonly used in the manufacture of garments, upholstery textiles, curtains, cushions and other textile products. It can be used to fasten pieces together, create hems, reinforce areas of tension, and even create decorative patterns.

Paper sizing is used in many creative and practical fields. These include book binding, card and album making, collage art, decorations and crafts, and repairing torn documents.

Fabric and paper sizing can be permanent or temporary, depending on the type of glue used. Some glues allow permanent sizing, making the bond difficult to undo.

A project ?

Contact us

Contact us for any fabric or paper gluing project, and our team will respond as soon as possible.